ExtremeTemperatures

Optical fiber assemblies resistant to extreme temperatures

Thanks to its know-how and expertise, SEDI-ATI Fibres Optiques can offer you optical fiber-based assemblies or solutions capable of withstanding extreme temperatures of up to +800 °C, or even 1,000 °C with sapphire fiber.

Resistance to extreme temperatures

The melting point of silica is around 1,700 °C, so a bare optical fiber could easily fulfil its data transmission role at such temperatures. However, deprived of mechanical protection, it becomes extremely vulnerable to shocks and vibrations. It is therefore the raw materials used in the design of the fiber assembly that will be the main limiting factor in terms of temperature resistance. Knowing the temperature gradient and the distance between hot spots will help to guide technological choices, so that silica fiber can be installed in environments of up to 800 degrees Celsius. Another alternative to silica fiber is sapphire fiber. Sapphire fibers have a crystalline structure that allows transmissions over a broad spectrum from 0.75 to 3.5 µm and over a temperature range from cryogenic to 2,000°C. The extreme hardness and inert nature of sapphire mean that this type of fibre can be used in extreme environments (such as industrial installations).

The problem

Corrosive or abrasive chemicals can contain aggressive substances to the optical fiber and the assembly, as these products can degrade coatings (particularly polymer materials) and various components such as connectors. This can lead to failures in the optical connection, compromising both mechanical integrity and optical properties, to the point of rending the solution unusable and creating risks to the safety of people and equipment.

OurExpertise

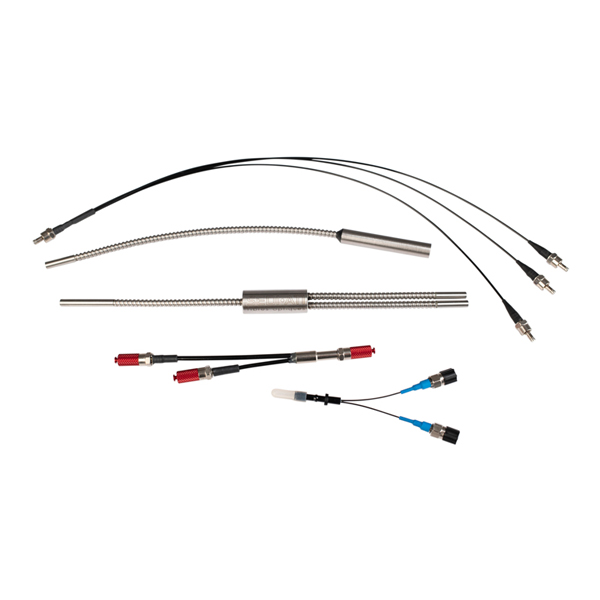

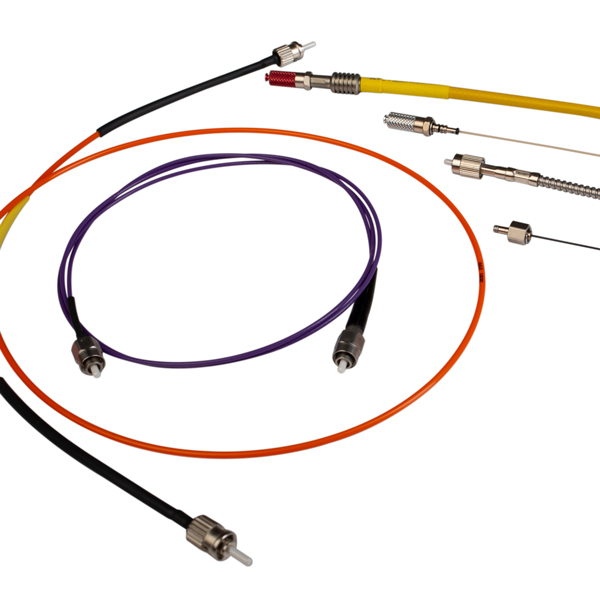

Our SEDI-ATI fiber optic assemblies can withstand extreme temperatures of up to +800 °C, and even 1,000 °C thanks to the sapphire fiber. The technological choices made correlate with the final application. Raw materials and assembly techniques are selected to ensure that the product is functional and viable over time in both severe (<125°C) and extreme (>125°C) environments.

SEDI-ATI Fibres Optiques manufactures its products to withstand extreme temperatures by selecting the fiber from its wide range of high-temperature acrylate, polyimide, aluminum and copper-coated fibers. Finally, the sealing technics are adapted to the application (epoxy, brazing, glass-soldering, etc.).

All our ranges of bundles, connectors, special fiber optic cables and patchcords, couplers, multiplexers, hermetic feedthroughs, etc. can be customised to meet your requirements. For this type of application, we offer silica/sapphire assemblies for parts located in your high-temperature environment, as well as the use of sapphire windows at the end of your assembly to protect the optical face of your customised solution.